-

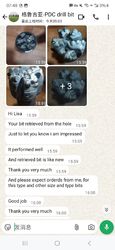

Rita.La qualità del bit di tricone è buona.

Rita.La qualità del bit di tricone è buona. -

Guramil tuo bit recuperato dal foro, ti informo che sono sotto pressione, ha funzionato bene. E il bit recuperato è come nuovo.

Guramil tuo bit recuperato dal foro, ti informo che sono sotto pressione, ha funzionato bene. E il bit recuperato è come nuovo.

Diamante 4-1/2" PDC Foratura Strumento di perforazione del petrolio

Contattatemi per campioni e buoni.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se avete qualche problema, offriamo assistenza online 24 ore su 24.

x| Trattamento superficiale | Inserto PDC | Utilizzo | perforazione di pozzi di petrolio |

|---|---|---|---|

| Industriale | Perforazione e sotto buco | Parametri operativi | Coppia alta e bassa WOB |

| Caratteristiche | Elevata resistenza all'abrasione e resistenza al calore | Vantaggio | Alta efficienza, alta resistenza |

| Formazione | Molto duro | Tipo di taglio | 1310 |

| Formazione rocciosa | 8 | Ugelli | 3 |

| Evidenziare | 4-1/2 inch PDC drill bit,oil drilling PDC bit,matrix body PDC drill bit |

||

Punta da trapano PDC da 4-1/2" per trivellazione petrolifera

1. Descrizioni della punta da trapano PDC

La punta PDC è uno strumento di perforazione a taglio fisso con taglienti in diamante policristallino compatto utilizzato per la perforazione di rocce in pozzi petroliferi, minerari, idrici o di gas. Questo strumento di perforazione è fabbricato secondo le specifiche API ed è certificato API. I taglienti PDC sono realizzati in materiale diamantato sintetico, che è il materiale più duro conosciuto, rendendolo estremamente resistente all'usura. Rispetto alle punte tricono, le punte PDC offrono generalmente una maggiore efficienza di perforazione, ma a un costo maggiore.

Le punte PDC utilizzano molteplici taglienti diamantati disposti secondo schemi specifici per tagliare la formazione rocciosa. Queste punte sono principalmente classificate in due tipi: punte PDC a corpo matrice e punte PDC a corpo in acciaio, progettate per diverse condizioni di perforazione. Le punte PDC a corpo matrice sono tipicamente utilizzate in formazioni più abrasive, mentre le punte PDC a corpo in acciaio sono spesso impiegate in formazioni più morbide.

2. Specifiche:

Le punte PDC come la S616 o la M616 sono specificate con un corpo in acciaio o matrice a 6 lame e un tagliente principale da 16 mm. Il codice IADC indica se la punta è adatta per formazioni dure, morbide o con profilo specifico, fornendo ulteriori informazioni.

Quindi l'IADC 323 ha un significato diverso per la punta da trapano PDC.

| SPECIFICHE | |

| Dimensione: | 4-1/2 pollici (14,3 mm) |

| Tipo di corpo della punta: | Corpo matrice |

| Quantità di lame: | 5 |

| Quantità di ugelli: | 3 |

| Attacco API (in): | 2-7/8" REG |

| Lunghezza di calibro (in): | 1 |

| PARAMETRI OPERATIVI | |

| Peso sulla punta (KN): | 9-67 |

| Gamma RPM (Rotazione): | 80- DHM |

| Portata (lps): | 11- 15 LPM |

| Coppia di serraggio (KN): | 9,5 - 12,2 KN.M |

![]()

![]()

![]()

3. Profilo della punta da trapano PDC

![]()

4.Taglienti PDC della punta da trapano

Al centro di una punta da trapano ci sono i taglienti in diamante policristallino composito (PDC), che interagiscono direttamente con la roccia, utilizzando principalmente l'azione di taglio per la rimozione. Nell'ambiente impegnativo di un pozzo, i taglienti PDC subiscono frequenti cicli di riscaldamento e raffreddamento, che pongono sfide significative.

I taglienti PDC con una migliore stabilità termica e una ridotta degradazione termica tendono a funzionare meglio, con conseguente aumento dei tassi di penetrazione (ROP) e una migliore resistenza all'usura. L'ottimizzazione di questi taglienti è quindi fondamentale per massimizzare l'efficienza.

![]()

5. Ugelli della punta da trapano PDC

Gli ugelli della punta da trapano PDC aiutano a pulire l'area di taglio e a raffreddare i taglienti in diamante policristallino composito (PDC).

Il posizionamento efficace di questi ugelli insieme all'angolo in cui sono impostati gioca un ruolo fondamentale sull'efficienza della punta da trapano.

I canali dei fluidi completano anche il posizionamento degli ugelli per migliorare la pulizia dei detriti.

![]()

6. Caratteristica opzionale della punta da trapano PDC:

Ci sono molte più caratteristiche della punta da trapano PDC tra cui scegliere, che aumentano la stabilità, la resistenza all'usura e le prestazioni dei taglienti della punta PDC.

7. Punte PDC a corpo in acciaio

Il corpo in acciaio della punta PDC è l'opposto del corpo matrice. Può resistere a carichi ad alto impatto, ma è più morbido e privo di caratteristiche protettive. La resistenza e la duttilità dell'acciaio conferiscono ai corpi delle punte in acciaio un'elevata resistenza agli urti.

I corpi in acciaio sono notevolmente più resistenti dei corpi matrice.

Capacità del materiale e standard di riferimento

API

| ISO | ASM | NACE | 8. |

| ISO 9001 | ASME B94.55M ASME B94.11M | NACE | 8. |

Tutte le punte da trapano saranno testate come segue:

---Strumenti di prova meccanica

---Test di durezza

---Test UT

---Altri test in base alle esigenze