-

Rita.La qualità del bit di tricone è buona.

Rita.La qualità del bit di tricone è buona. -

Guramil tuo bit recuperato dal foro, ti informo che sono sotto pressione, ha funzionato bene. E il bit recuperato è come nuovo.

Guramil tuo bit recuperato dal foro, ti informo che sono sotto pressione, ha funzionato bene. E il bit recuperato è come nuovo.

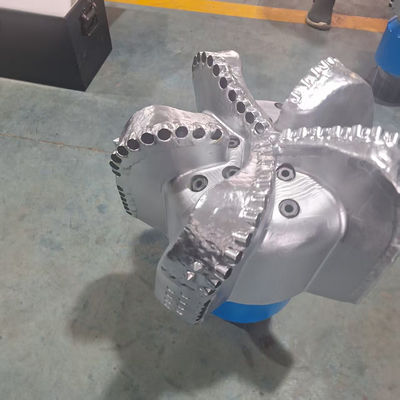

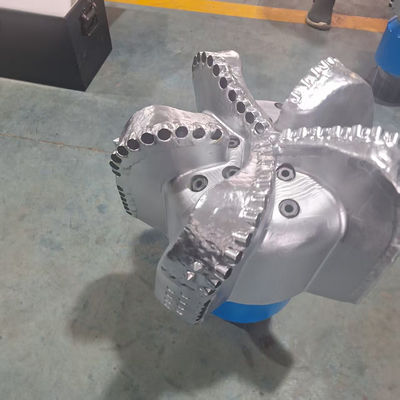

17-1/2 " PDC Drill Bit of Oil Well Rock Drilling Tool

| Luogo di origine | Cina |

|---|---|

| Marca | ENG |

| Certificazione | API, ISO |

| Numero di modello | 1750 |

| Quantità di ordine minimo | 1 |

| Prezzo | 1000-20000 |

| Imballaggi particolari | Scatola di legno e scatola di metallo |

| Tempi di consegna | 4 settimane |

| Termini di pagamento | T/T, L/C, Western Union |

| Capacità di alimentazione | 5000pcs / anno |

Contattatemi per campioni e buoni.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se avete qualche problema, offriamo assistenza online 24 ore su 24.

x| Misurare | 17. 50 "(444,50 mm) | Tipo | Tagliente di PDC |

|---|---|---|---|

| Lame | 5Blades | Utilizzo | Bene per la perforazione del petrolio e del gas |

| Materiale | Acciaio diamante e lega | Tipo di macchina | Industria di perforazione |

| Tipo di elaborazione | Forgiando, casting | Applicazione | Trapano roccioso di petrolio, mining, gas |

| Colore | Requisito del cliente | Vantaggio | Alta efficienza, alta resistenza |

| Diametro del taglio | 16 mm | Mercato | in tutto il mondo |

| Imballaggio | Scatola d'acciaio | Tipo di taglio | 1613 |

| Formazione rocciosa | f <8 | Ugello qunatity | 10 |

| Taglierine | Polycristalline Diamond Compact (PDC) | Tipo | Bit per trapano diamantato |

| Trattamento superficiale | Inserto PDC | ||

| Evidenziare | 17-1/2 inch PDC drill bit,oil well rock drilling tool,steel body PDC drill bit |

||

17-1/2 " PDC Drill Bit of Oil Well Rock Drilling Tool

1 . Descriptions:

PDC bit is a fixed cutter drilling tool with polycrystalline diamond compact cutters used for rock drilling in oil, mining, water or gas wells.

This drilling tool is manufactured according to API specifications and is API certified. The PDC cutters are made of synthetic diamond material,

which is the hardest known material, making it extremely wear-resistant. Compared to tricone bits, PDC bits generally offer higher drilling

efficiency but at a higher cost.

PDC bits utilize multiple diamond cutters arranged in specific patterns to shear the rock formation. These bits are mainly categorized

into two types: matrix body PDC bits and steel body PDC bits, designed for different drilling conditions. Matrix body PDC bits are

typically used in more abrasive formations, while steel body PDC bits are often employed in softer formations.

According to the International Association of Drilling Contractors (IADC), there are much reason effected the bit drilling function effiency .

We have give the main reason as below :

- Body material

- Cutter density

- Cutter size or type

- Bit profile

All of the drill bit are manufacture according to API standard used in the drilling Industry.

The PDC drill bits size 3~22inch with 3~9Blades are available. And different classification cutter are optional according to your budget .

2. Specification:

| SPECIFICATION | |

| Size : | 17-1/2 "(444.50mm) |

| Drill Body Type : | Steel Body |

| Blades Quantity : | 5 Blades |

| Nozzles Quantity : | 10 |

| API Connection (in) : | 7-5/8" REG |

| Gauge Length (In): | 4 |

| OPERATIONAL PARAMETERS | |

| Weight on Bit (KN): | 67 -200 KN |

| RPM Range(Rotary): | 100 - DHM |

| Flow Rate(lps): | 57 - 75 LPM |

| Make-Up Torque(KN): | 82--92 KN.M |

![]()

![]()

3 . PDC Bit profile

![]()

4 . Drill Bit PDC Cutters

Polycrystalline Diamond Composite (PDC) cutters are the main point of contact for a drill bit. PDC bits remove the rock mainly by shearing.

The PDC cutters are exposed to a lot of heating and cooling down the well, a very challenging environment.

PDC cutters that have lower thermal degradation and more thermal stability generally achieve higher ROP and increased wear resistance. So, optimizing the cutter is important.

![]()

5. Drill Bit Nozzles

Drill bit nozzles help clear the cutting area and cool the Polycrystalline Diamond Composite (PDC) cutters.

Effective placement of these nozzles along with the angle they are set at plays a critical role on how efficient the drill bit performs.

Fluid channels also complement nozzle placement to improve the clearing of cuttings.

![]()

6. Steel Body PDC Bits

Steel body is the opposite of matrix body. It can of withstanding high impact loads, but is softer and lacks protective features. The strength and ductility of steel give steel-bit bodies high impact resistance.

Steel bodies are considerably stronger than matrix bodies.

A beneficial feature of steel bits is that they can easily be rebuilt a number of times because worn or damaged cutters can be replaced rather easily. This is a particular advantage for operators in low-cost drilling environments.

![]()

Polycrystalline diamond compact (PDC) drill bits are different than roller cones in that they are one piece bodies with no moving parts. The fixed-cutters shred the rock, so the bit is able to operate with higher rotation speeds more efficiently in consolidated formations.

![]()